* The preview only shows a few pages of manuals at random. You can get the complete content by filling out the form below.

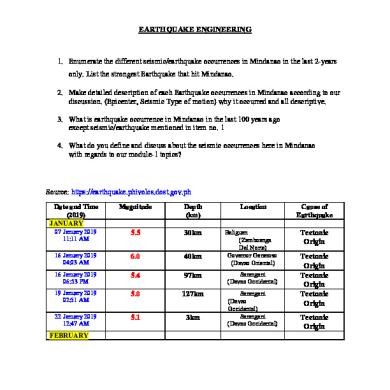

Description

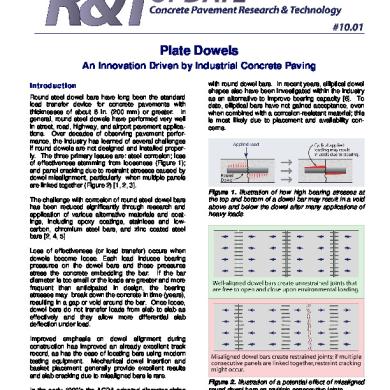

Plate Dowels An Innovation Driven by Industrial Concrete Paving Introduction Round steel dowel bars have long been the standard load transfer device for concrete pavements with thicknesses of about 8 in. (200 mm) or greater. In general, round steel dowels have performed very well in street, road, highway, and airport pavement applications. Over decades of observing pavement performance, the industry has learned of several challenges if round dowels are not designed and installed properly. The three primary issues are: steel corrosion; loss of effectiveness stemming from looseness (Figure 1); and panel cracking due to restraint stresses caused by dowel misalignment, particularly when multiple panels are linked together (Figure 2) [1, 2, 3]. The challenge with corrosion of round steel dowel bars has been reduced significantly through research and application of various alternative materials and coatings, including epoxy coatings, stainless and lowcarbon, chromium steel bars, and zinc coated steel bars [2, 4, 5]

with round dowel bars. In recent years, elliptical dowel shapes also have been investigated within the industry as an alternative to improve bearing capacity [6]. To date, elliptical bars have not gained acceptance, even when combined with a corrosion-resistant material; this is most likely due to placement and availability concerns.

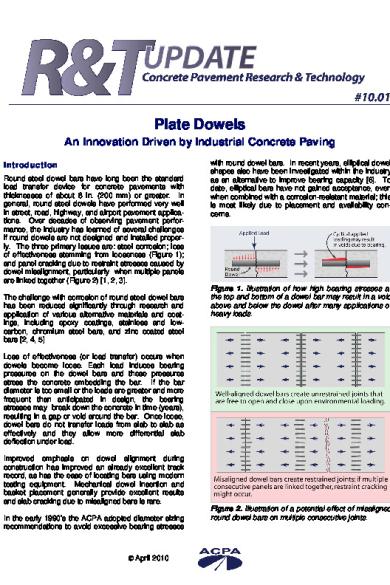

Figure 1. Illustration of how high bearing stresses at the top and bottom of a dowel bar may result in a void above and below the dowel after many applications of heavy loads.

Loss of effectiveness (or load transfer) occurs when dowels become loose. Each load induces bearing pressures on the dowel bars and these pressures stress the concrete embedding the bar. If the bar diameter is too small or the loads are greater and more frequent than anticipated in design, the bearing stresses may break down the concrete in time (years), resulting in a gap or void around the bar. Once loose, dowel bars do not transfer loads from slab to slab as effectively and they allow more differential slab deflection under load. Improved emphasis on dowel alignment during construction has improved an already excellent track record, as has the ease of locating bars using modern testing equipment. Mechanical dowel insertion and basket placement generally provide excellent results and slab cracking due to misaligned bars is rare. In the early 1990’s the ACPA adopted diameter sizing recommendations to avoid excessive bearing stresses

© April 2010

Figure 2. Illustration of a potential effect of misaligned round dowel bars on multiple consecutive joints.

Figure 3. Dowel sockets, resulting from spinning a dowel bar into place to aid form removal, may lead to accelerated joint faulting and spalling.

Performance Issues on Industrial Pavements Critical joint performance issues are somewhat different in industrial paving applications than for streets, roads, highways and airports. Industrial applications almost always require wide-bay construction because paving areas cover large expanses. Pavements are placed in both interior and exterior situations, and the placement methods also may vary considerably from roadway construction. Often, industrial pavements extend for hundreds of feet in either direction, as opposed to roadways that are typically 24 to 28 ft (7.3 to 8.5 m) wide. Doweling usually occurs in both directions, and as a result, dowel alignment issues are a more common problem with industrial pavements. Airport pavements also cover large expanses, but they are generally much thicker and more forgiving to dowel alignment issues. Within the past 10 to 15 years, engineers working with concrete pavements at industrial facilities have observed accelerated joint faulting and spalling. These distresses have been attributed to a transition from an industrial vehicle fleet (forklifts and other equipment) with large, pneumatic tires to ones with mostly small, hard wheels. Although such joint distresses are a result of differential displacement and deflection at the joints, the extremely high bearing stresses on round dowels under the smaller, harder wheels are hypothesized as a primary catalyst to dowel looseness and significant joint deflection. Engineers now seek to control joint deflection as part of industrial pavement design, which is a major difference from concrete pavement design for other applications. Also of concern with industrial paving, sometimes a socket is created around dowels as they are twisted into the pavement edge at construction joints (Figure 3) to aid form removal [7]. The result is a void inadvertently constructed around the dowel before the pavement is opened for service. Performance of the joint constructed with voids will be similar to a joint with

Page 2

an elongated dowel socket caused by many years of service under high bearing pressures. Similarly, enlarged dowel sockets also have been noted in the industrial paving industry at locations where uncontrolled amounts of grease were used on dowels as a bond breaker [8]. While good construction practices may be employed to avoid these problems, they still occasionally occur, particularly with inexperienced construction personnel. Lastly, because of the wide-bay construction and twodirectional doweling characteristic of industrial concrete pavement, dowel misalignment that results in locking of joints might lead to a higher risk for panel cracking than is typical in other applications; it is more challenging to control dowel basket alignment over longer distances than it is where baskets are placed in a shorter, controlled strip or lane placements. This has led to innovations aimed at providing some degree of freedom for dowels to shift laterally or tolerate some misalignment within their socket.

The Evolution of Plate Dowels Square Bars – The first attempt to move away from round dowels in industrial concrete paving was made in the late 1980’s [9]. This attempt used square dowels with compressible material attached to the vertical faces. The aim of this technology was to provide adequate load transfer while also allowing for lateral movement of the slabs by way of the compressible material on each vertical face. Further improvements included a high density plastic (ABS) clip that was added to the square-dowel design to hold the compressible material in place during construction [10]. Rectangular Plates – In the mid-nineties, a rectangular plate dowel was introduced to extend the square dowel concept. Rectangular plate dowels decrease bearing stresses by spreading load over a larger area relative to round or square bars. Plastic clips with compressible material were also introduced with the rectangular plate dowels to allow for lateral movement

Number 10.01

and some misalignment [11]. Joint deflection control was also considered to be better with the increase in bearing area. Refined Plates – Refinements to the original plate dowel concept have led to a variety of plate dowel shapes now in full-scale use, including diamond, tapered and double-tapered [11, 12, 13]. These shapes were introduced to: Provide more bearing area, Eliminate the need for compressible material on vertical faces (required for square bars and rectangular plates to provide a degree of freedom for lateral shifting or misalignment), and Potentially allow for wider spacing between bars (depending on the plate geometry) compared to square or round bars. Some of the various dowels currently provided by manufacturers are summarized in Figure 4. This is an area of continual development and plate dowel manufacturers have patents on certain shapes, attachments and installation techniques. Each type has associated limitations and benefits, and may come in various thicknesses or lengths. ACPA encourages engineers and contractors to investigate these factors with manufacturers before selecting and using plate dowels on a project.

Basic Benefits of Plate Dowels Steel Quantity – Depending on geometry, plate dowels may be able to provide the same load transfer benefit at a larger spacing than traditional round or square dowel bars. This potential saves steel and may reduce project costs.

Typical round dowel dimension specifications are based on providing a sufficient length and diameter to mitigate bearing stresses, as well as sufficient embedment length to maximize load transfer. A saw cut tolerance of 1 to 3 in. (25 to 75 mm), to either side of the mid-length of the dowel is commonly specified, depending on the bar length. The embedment length necessary for a typical round dowel to be effective is 6 in. (150 mm). With available plate dowel products, the necessary embedment length may be considerably less. This, coupled with the potential to increase dowel spacing, can result in an overall reduction in the quantity (volume) of steel required at each joint by as much as 30-75%, depending on which plate dowel technology and spacing is determined to be an equivalent replacement of a round dowel specification. The key design factors are dowel bearing area and area of steel below the joint. ACPA recommends specifying a plate dowel design with at least an equivalent area of steel at the joint face and an equivalent bearing area to that of a traditional round dowel bar design acceptable for the application. No matter what size or shape is selected it must have enough embedment depth to be effective and to provide some tolerance for constructability. Since manufacturers produce standard plate sizes, an equivalent bearing area per length of joint is found by adjusting the spacing between plates to meet or exceed the bearing area along a joint provided by traditional round bars. Size and spacing recommendations for round dowel bars are relatively standard (see ACPA TB010P). To calculate the area of steel is also relatively simple, although the saw cutting tolerance will need to be factored into the calculation for contraction joints. First determine the area of steel per foot of joint for the round dowel design and then do the same for the plate dowels. When calculating the plate dowel steel area per foot, use the effective area of the plate dowel at the maximum offset allowable by the sawing tolerance. The results will depend upon the plate dowel geometry (including thickness) [8].

Figure 4. Some of the various dowel shapes used commonly in industrial and concrete paving.

April 2010

Reduce Lateral Slab Restraint – Diamond, tapered and double-tapered plate dowels greatly reduce slab restraint without the need for a compressible material on the vertical faces of the plates [13]. Joint movement is accommodated by dowel geometry alone (Figure 5). The void created around a plate dowel provides some additional forgiveness for misalignment during construction without negatively impacting load transfer performance. The void also accommodates some lateral shifting without restraint.

Page 3

(50 mm) to either side of the joint for slab on ground construction [14]. Saw cut alignment relative to the dowel baskets is also important. Should an operator make a saw cut on an angle from the actual basket location, some dowels may be rendered ineffective. Such an error is magnified with longer contraction joint cuts. Contractors should use accurate paint marks or marking nails to identify the basket center on either edge of paving and snap an accurate chalk line for the saw operator to follow. Figure 5. Conceptual drawing that shows how plate geometry allows for a void to develop when the concrete shrinks and contracts after placement.

Installation Considerations Formed Construction Joints – To install plate dowels in formed construction joints, pocket formers are attached at the proper location on the forms (Figures 6a and 6b) or a special form with precut slots is used. After removing the forms, a plate dowel is slipped into each pocket former [13]. This procedure provides an installation with a reasonable construction tolerance and uniform embedment.

Contractors must be aware that designers are encouraged to consider the worst-case plate width at the maximum sawing tolerance offset when developing size and spacing requirements for plate dowels. Therefore, the intent of the design will be met only as long as saw operators control sawing within the tolerance limits. Contractors who saw out of tolerance are likely subject to price reductions or other mitigation considerations. In any case, when a properly constructed contraction joint opens, voids around the ends of tapered dowels are created, allowing for lateral movement and a degree of misalignment without inducing restraint.

Because diamond plate dowels create a void that is larger than the dowel upon opening of a joint (similar to what is shown in Figure 5), their geometry allows for some unrestrained lateral movement of the slabs; some rectangular plate dowel formers, such as those shown in Figure 6b, also allow for some unrestrained lateral slab movement by way of centering tabs inside a wider square pocket former. The tabs will deform, accommodating movement whenever lateral loads are applied. Contraction Joints – Plate dowel baskets are now used commonly in contraction joints in many industrial paving applications (Figures 7a and 7b). Sawing location tolerances are very important at contraction joints, particularly long contraction joints typical of industrial site construction. The plate dowel configuration should provide a reasonable and enforceable sawing tolerance. Securing baskets is vital in order to meet specified tolerances and should not be overlooked even where a vapor barrier is required. A tolerance of 1 in. (25 mm) to either side of a secured the plate dowel basket centerline is reasonable for roadway lane placements; the tolerance needs to be larger where contraction joints span longer distances and snapping stringlines for saw guidance may be less accurate, or where basket placement is performed on the fly for laser screed operations, or for other site conditions. American Concrete Institute (ACI) guidance on plate dowels provides for a tolerance of 2 in.

Page 4

Figure 6a. Installation of a diamond plate dowel pocket former on wooden construction joint form [photo courtesy of PNA Construction Technologies, Inc.].

Figure 6b. Square pocket former for rectangular plate dowels installed on a wooden construction joint form [photo courtesy of Greenstreak Group, Inc.].

Number 10.01

Slab Corners – ACPA has not tested joint installations to determine a recommended specification on how close plate dowels may be to another doweled joint, but current ACI guidance specifically allows diamond plate dowels to be within 6 in. (150 mm) [14]. ACPA believes this to be reasonable guidance for any plate dowel configuration that that is designed to accommodate lateral movement. However, it is also important to factor in the saw cut tolerances at contraction joints for proper positioning of dowel baskets near slab corners.

Corrosion: an Issue under Development Figure 7a. Single taper plate basket with alternating bars [photo courtesy of PNA Construction Technologies, Inc.].

Corrosion of steel dowel plates remains an area of development. Because most industrial concrete pavements are placed in the confines of indoor or covered facilities, corrosion has not been a major roadblock to the use of plate dowels in industrial concrete paving. Knowing that corrosion protection is likely a concern for most outdoor applications, plate dowel manufacturers currently are investigating corrosion protection alternatives similar to those discussed earlier for round dowels.

Potential Applications Despite their widespread use in industrial concrete paving, plate dowels have not been introduced into other paving applications. Plate dowel baskets are only just being introduced for use in other paving applications. Use in thinner concrete street and road designs seems a potential fit. Figure 7b. Double taper plate basket [photo courtesy of Greenstreak Group, Inc.].

Figure 8. Slipform paving an industrial pavement that includes tapered plate dowel baskets. Note that the pavement was 8 in. thick and the dowel baskets were positioned just in front of slipform paving operations, allowing the prepared subgrade to be used as a haul road. [photo courtesy of PNA Construction Technologies, Inc.].

April 2010

Plate dowel baskets were recently used for the first time in conjunction with slipform paving operations with good results (Figure 8). Although this was an industrial paving application, it indicates the potential viability of plate dowel baskets for roadway paving methods. Other more specialized applications might derive important performance benefits from plate dowels. For example, the unique ability of plate dowels that allows for a degree of freedom within their sockets laterally could benefit joints in curves. Each dowel itself can move in the socket a little as a joint opens up even the smallest amount, which prevents restraint and associated stresses. Applications might include tight radius curves in residential pavements, or joints within roundabout intersection where traditional round dowel bars might lock a joint even if they are properly aligned. The ability to allow lateral movement might also make plate dowels useful alternatives in intersections or other places where four joints meet, a location where excellent load transfer at corners may be extremely beneficial but placing round dowel bars too near the joint may increase the risk of corner cracks (Figure 9).

Page 5

Based on the history of success in industrial concrete paving and the considerable cost of steel, evaluation of plate dowel technologies for other concrete paving applications is likely to develop rapidly. Introduction of plate dowels to parking lot, street and rural road pavements likely will be the primary area of advancement. Introduction of plate dowels in highway construction will require further study and advancements, particularly with regard to: Performance under heavy channelized truck traffic, Optimal placement configurations, Capability for placement through mechanized dowel insertion machinery, and Corrosion resistance.

Figure 9. Traditional round dowel bars located too close to a joint intersection may cause corner cracking due to restraint stresses; the freedom to move laterally with diamond plate dowels can mitigate restraint stresses.

References 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14.

Page 6

“Evaluating and Optimizing Dowel Bar Alignment,” American Concrete Pavement Association, SR999P, August 2006. Porter, M.L., and Guinn, R.J., “Assessment of Dowel Bar Research,” Center for Transportation Research and Education, August, 2002. “TechBrief: Best Practices for Dowel Placement Tolerances,” Federal Highway Administration, FHWA-IF-07-021, 2007. “High Performance Concrete Pavements: Alternative Dowel Bars for Load Transfer in Jointed Concrete,” Federal Highway Administration, FHWA-IF-02-052, 2002. “Summary of Independent Testing,” MMFX Technologies Corporation, 2004, . Porter, M.L., Guinn, R.J., and Lundy, A.L., “Dowel Bar Optimization: Phase I and II,” Center for Transportation Research and Education, October, 2001. Fricks, G.K., and Parkes, N.K., “Innovations for Durable Floors,” Concrete Construction, January 2002. Walker, W.W., and Holland, J.A., “Performance-Based Dowel Design,” Concrete Construction: The World of Concrete, January, 2007. Schrader, E.K., “A Proposed Solution to Cracking Caused by Dowels,” Concrete Construction, 1987. Schrader, E.K., “A Solution to Cracking and Stresses Caused by Dowels and Tie Bars,” Concrete International, pp. 4045, July, 1991. Walker, W.W., and Holland, J.A., “Dowels for the 21st Century: Plate Dowels for Slabs on Ground,” Concrete International, pp. 32-38, July, 1998. Parkes, N.K., “Designing the Cost-Effective Slab-on-Ground,” Structure Magazine, April 2007. Parkes, N., “A Decade of Dowel Development,” L&M Concrete News, January, 2007. “Guide for Concrete Floor and Slab Construction,” ACI 302.1R-04.

5420 Old Orchard Road, Suite A100, Skokie, IL 60077 Tel.: 847.966.2272; Fax: 847.966.9970; www.pavement.com

Number 10.01